Description

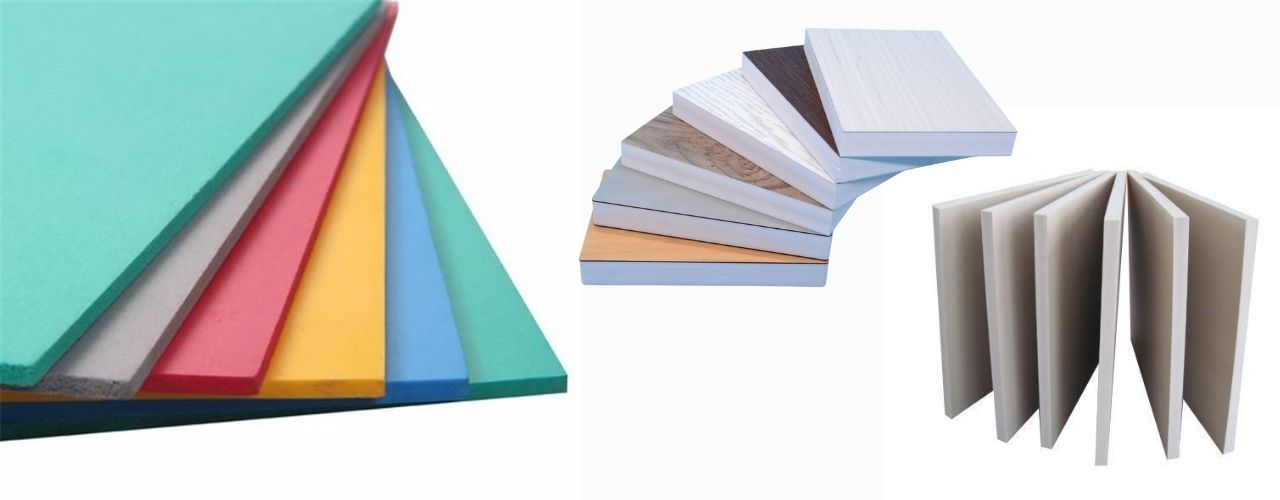

WPC/PVC foam board extrusion line for the production of panels, boards and sheets as an alternative to natural wood panels and plywood. WPC/PVC foam board extrusion line can produce PVC or WPC foam boards in sizes from 1220 to 1560 mm and thicknesses from 3 mm to 30 mm. PVC foam board extrusion line produce panels, boards, sheets and other end products for construction and furniture. The product utilizes wood and plastic. It has the appearance of natural wood and overcomes the disadvantages of wood. It can be machined, sawed, stapled and done with wood tools as easily as wood. It has significantly better holding power than ordinary wood materials. It has physical properties similar to those of hardwood, such as resistance to compression and impact, and its durable features are significantly better than those of ordinary wood. Wood plastic material and its products can resist strong acid and alkali, water and corrosion. In addition, bacteria cannot breed on it. It is not insect-infested. It can be used as anti-aging and anti-static flame retardant.Parameters

| Extruder | Model | Motor Power | Raw Material | Width | Capacity/H |

| Conical Twin Screw Extruder | SJSZ80/156 | 75KW | PVC Powder and Calcium Carbonate | 1220-1560 mm | 400 KG |

| SJSZ80/156 and SJSZ65/132 Co-Extrusion | 75KW + 37KW |

PVC Powder and Calcium Carbonate |

1220-1560 mm |

600 KG |

Flow Chart

Crusher (crushing the edge of board trimmed) → Miller (milling the scraps into powder) → Mixer (mixing the main materials and additives) → Auto loader→ conical double Screw Extruder → T-type forming die →

Calibration table → Cooling Bridge → Eight-roller haul-off→ Cutter with PLC control → Automatic Lifting Machine

Equipments

PVC Foam Board

WUXI JKS MACHINERY MANUFACTURING CO.,LTD

WUXI JKS MACHINERY MANUFACTURING CO.,LTD