Description

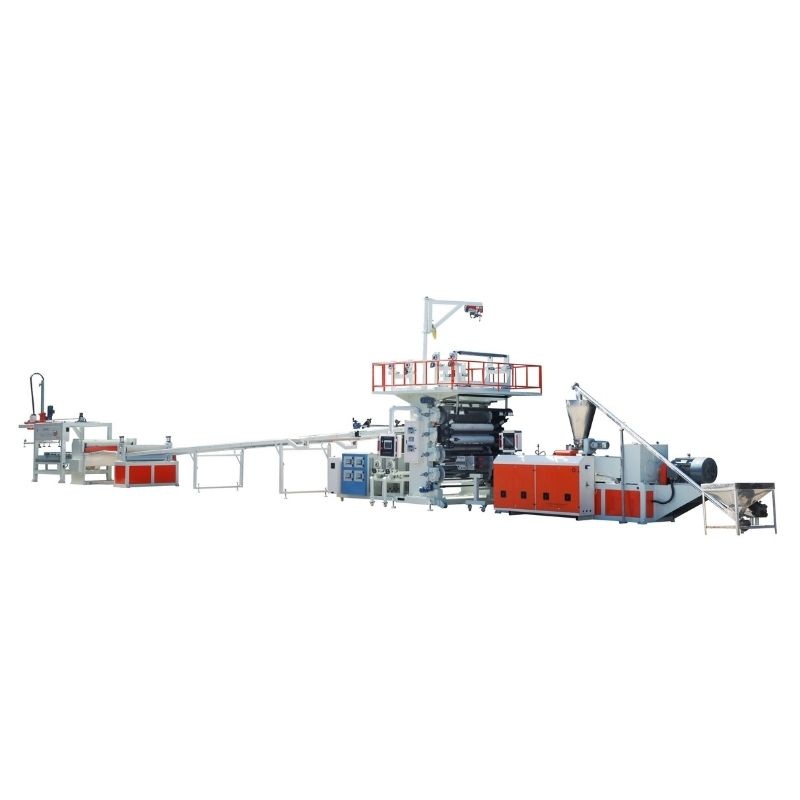

PVC Imitation Marble Sheet Production Line is used to produce PVC imitation marble sheet with width of 1220mm and thickness of 1-12mm. PVC imitation marble sheet production line has compact structure and superior performance. It is made of 38CrMoAIA high quality alloy steel with bimetallic coating on the surface.PVC imitation marble sheet is composed of PVC powder and calcium carbonate powder in the ratio of 1:2.5, so the cost is much lower than the real marble plate.

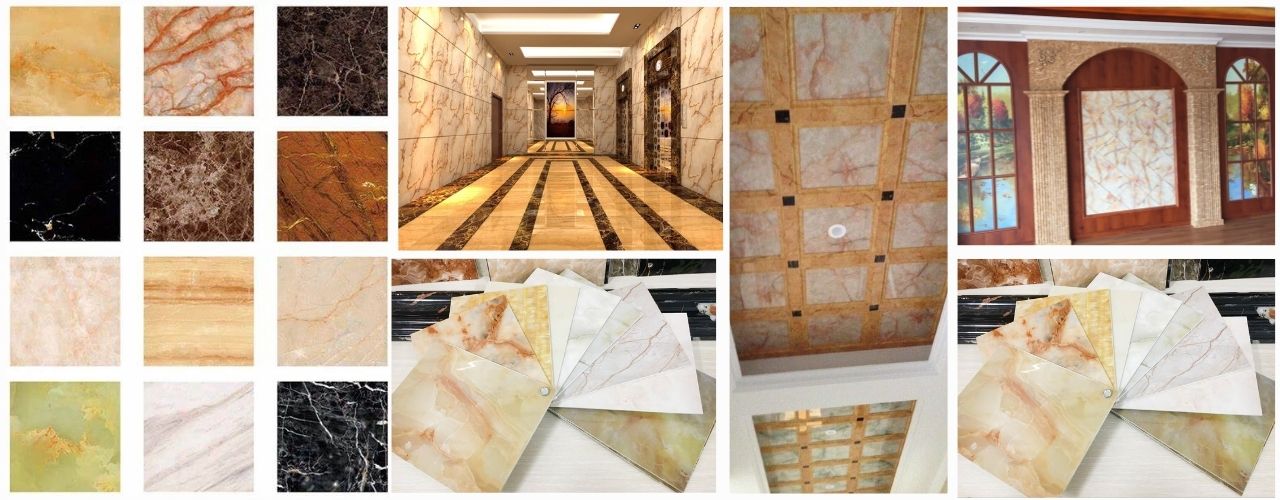

The application prospect of PVC imitation marble sheet is very broad. PVC imitation marble sheet is widely used for indoor decoration. It is suitable for prefabricated houses, factories, shopping malls, homes, offices and other occasions.

The surface has marble, carpet, stone, natural scenery and three-dimensional design. The products have marble pattern, granite pattern, imitation wood pattern, texture pattern, pure color semi-translucent heart and other patterns.

Parameters

Extruder |

Model |

Motor Power |

Raw Material |

Thickness |

Width |

Capacity/H |

Conical Twin Screw Extruder |

SJSZ80/156 |

75KW |

PVC Powder and Calcium Carbonate |

1-12 mm |

1220 mm |

400-500 KG |

SJSZ92/188 |

110KW |

PVC Powder and Calcium Carbonate |

1-12 mm |

1220 mm |

600-700 KG |

Flow Chart

Crusher (crushing the edge of board trimmed) → Miller (milling the scraps into powder) → Mixer (mixing the main materials and additives) → Auto loader→ conical double Screw Extruder → T-type Die →

Lamination Machine → Three-roller Calendar unit → Cooling Bridge → Haul-off Machine→ Edge Cutter→Transversal Cutter → Automatic Lifting Machine → UV Coating Machine

Equipments

PVC Imitation Marble Sheet

WUXI JKS MACHINERY MANUFACTURING CO.,LTD

WUXI JKS MACHINERY MANUFACTURING CO.,LTD