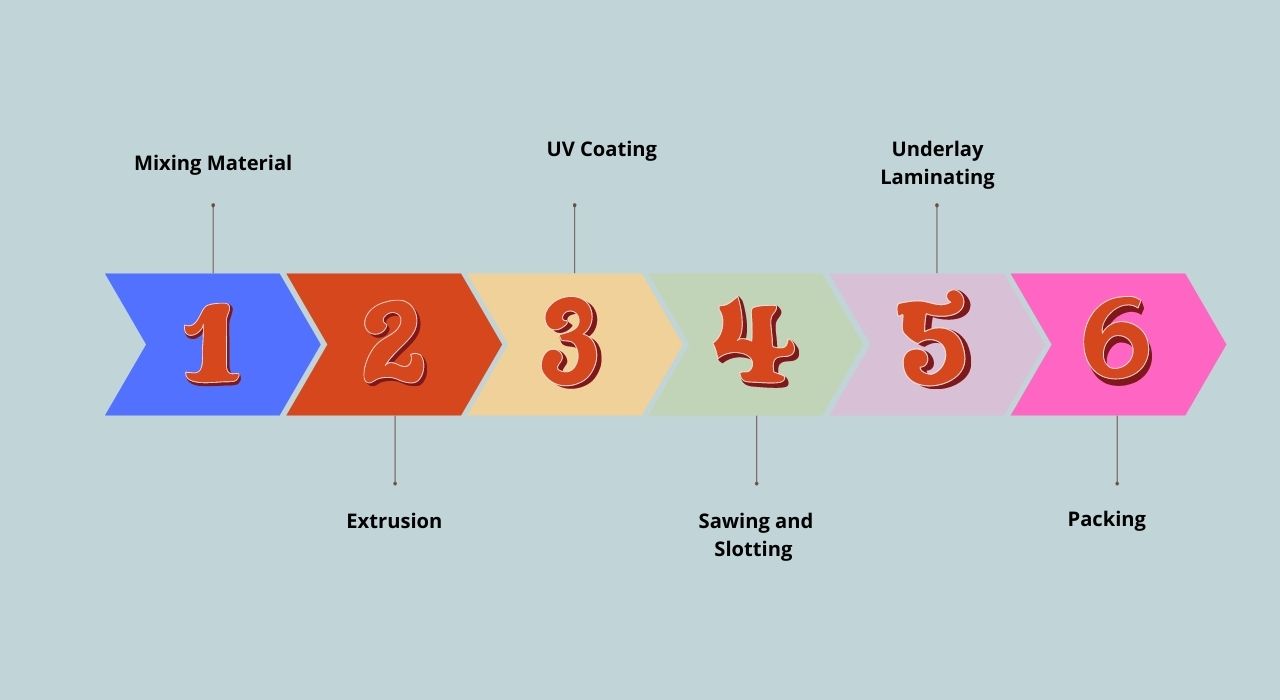

The SPC floor is extruded by the

SPC floor extrusion line. The PVC substrate is mainly extruded by an extruder combined with a T-shaped die, and the PVC wear-resistant layer, PVC color film and PVC substrate are thermally coated on-line with a four-roll or five-roll calender. Synthetic SPC floor, the process is simple, the lamination is done by heat, and no glue is required. SPC floor materials use environmentally friendly formula, do not contain heavy metals, phthalates, methanol and other harmful substances, in line with EN14372, EN649-2011, IEC62321, GB4085-83 standards. Compared with other floor decoration materials, the floor extruded by

SPC floor extrusion line will be more specific through the following characteristics,

1、Green environmental protection

SPC flooring production of the main raw material is high-quality polyvinyl chloride resin, is an environmentally friendly non-toxic renewable resources, natural environmental protection, 100% free of formaldehyde, benzene, heavy metals and carcinogens, insoluble in water volatiles, no radiation.

2、Ultra-light and ultra-thin

The thickness of SPC flooring is only 3-5mm, and the weight per square meter is only 2-5KG, less than 10% of ordinary flooring materials. In high-rise buildings, it has incomparable advantages in load-bearing and space-saving. At the same time, it has special advantages in the transformation of old buildings.

3、Super wear-resistant

The surface of SPC flooring has a special transparent wear-resistant layer processed by high technology, which fully ensures the excellent wear-resistant performance of the flooring material. The wear-resistant layer on the surface of SPC flooring depends on the thickness, and can be used for 10-15 years under normal circumstances. . Because of its super wear resistance, it is suitable for hospitals, schools, office buildings, shopping malls, supermarkets, vehicles and other places with high pedestrian flow.

4、High elasticity and super impact resistance

SPC flooring has a soft texture, so it has good elasticity, and has good elastic reply ability under the impact of heavy objects. At the same time, SPC flooring has strong impact resistance, and has strong elastic recovery ability under heavy impact damage without damage. . When people walk on SPC flooring, compared with traditional solid wood flooring and laminate wood flooring, it can greatly reduce the impact on the feet and reduce the proportion of people falling and getting injured.

5、Super anti-slip

The wear-resistant layer on the surface of SPC floor has a special anti-slip property, compared with ordinary flooring materials, SPC flooring feels more astringent in the case of sticky water, that is, the more water encountered, the better the anti-slip property. Therefore, it is suitable for public places with high public safety requirements, such as airports, hospitals, kindergartens, schools, etc.

6、Fire retardant

The main component of PVC plastic flooring itself is polyvinyl chloride, which is not easy to burn and can play the role of flame retardant to a certain extent. SPC flooring itself does not burn, can prevent combustion, and will not produce toxic and harmful gases.

7、Waterproof and moisture-proof

As the main component of SPC flooring is vinyl resin, there is no affinity with water, it can be used in a humid environment and will not be moldy due to high humidity.

8、Sound absorption and noise prevention

SPC floor has the sound-absorbing effect which is incomparable with ordinary ground materials, and the sound absorption can reach 20 decibels. Suitable for hospital wards, school libraries, lecture halls, theaters and other places, can provide a more comfortable and humane living environment.

9、Simple installation and easy maintenance

It can be cut arbitrarily with a hobby knife, and can also be combined with different color materials to meet the diversified and personalized decoration needs of consumers and achieve the most ideal decoration effect. And SPC flooring installation and construction does not require the use of building materials, only the installation of environmentally friendly flooring adhesive can be. The maintenance of SPC flooring only requires regular waxing or daily cleaning, and the maintenance frequency is much lower than that of traditional flooring materials.

10、Various colors

SPC flooring has a wide variety of colors, including carpet pattern, stone pattern, wood floor pattern, etc., and can even be customized. The lines are realistic and beautiful, with brightly colored accessories and decorative strips, which can be combined to create a beautiful decorative effect.

11、Resistant to acid and alkali corrosion

The surface of SPC flooring has been specially protected and has strong acid and alkali corrosion resistance. Therefore, it is very suitable for use in hospitals, laboratories, research institutes and other places.

12、Heat conduction and heat preservation

SPC flooring has good thermal conductivity, uniform heat dissipation and small coefficient of thermal expansion. So it is more suitable for home paving, especially for geothermal heating.

JKS Machinery is a company specializing in plastic extrusion technology research and related products or machine manufacturing. We support OEM/ODM services for overseas customers.

If you need the cost of SPC floor production line, we can also provide solutions for you to check and discuss with us. Feel free to let us know your details and requirements, we will reply you within 24 hours.